Industry News

-

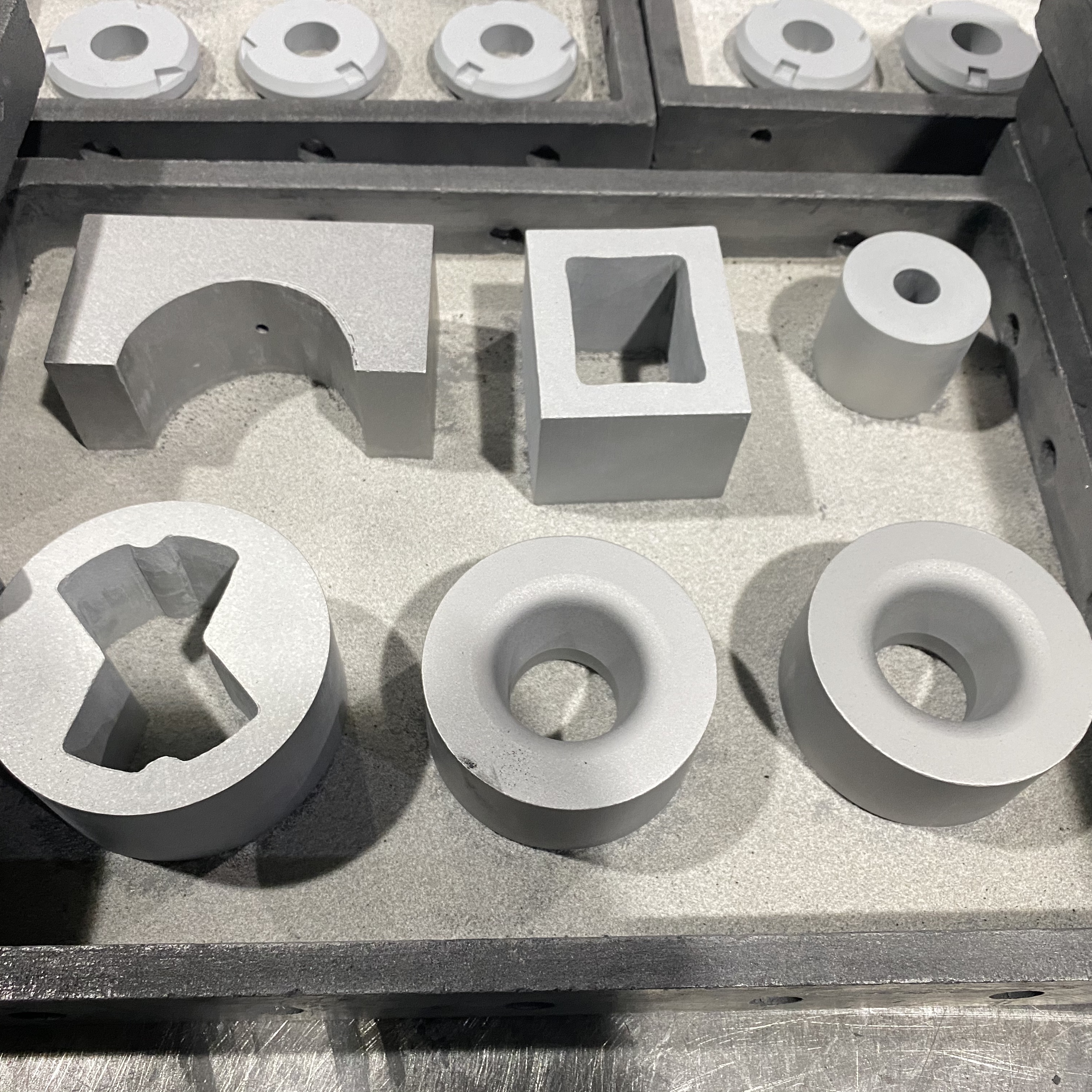

Tungsten Carbide Pressing Process

Cemented carbide pressing is a hard and highly wear-resistant material made by mixing metal powder (usually tungsten-cobalt or tungsten-titanium carbon, etc.) with a certain amount of binder, and then pressing and sintering. Cemented carbide has the characteristics of excellent wear resistance, c...Read more -

Applications of tungsten carbide hammer

A carbide hammer is usually a tool consisting of a metal head and a wooden handle. The head is usually made of cemented carbide, because cemented carbide has high hardness, high wear resistance and high fracture resistance. This material is better able to withstand repeated impact and stress, giv...Read more -

Cemented carbide drawing dies

Tungsten carbide drawing dies are widely used in the mechanical performance testing of metal and non-metal materials, including: 1. Metal materials: Carbide tensile dies are suitable for testing the mechanical properties of various metal materials, such as steel, copper, aluminum, magnesium, tit...Read more -

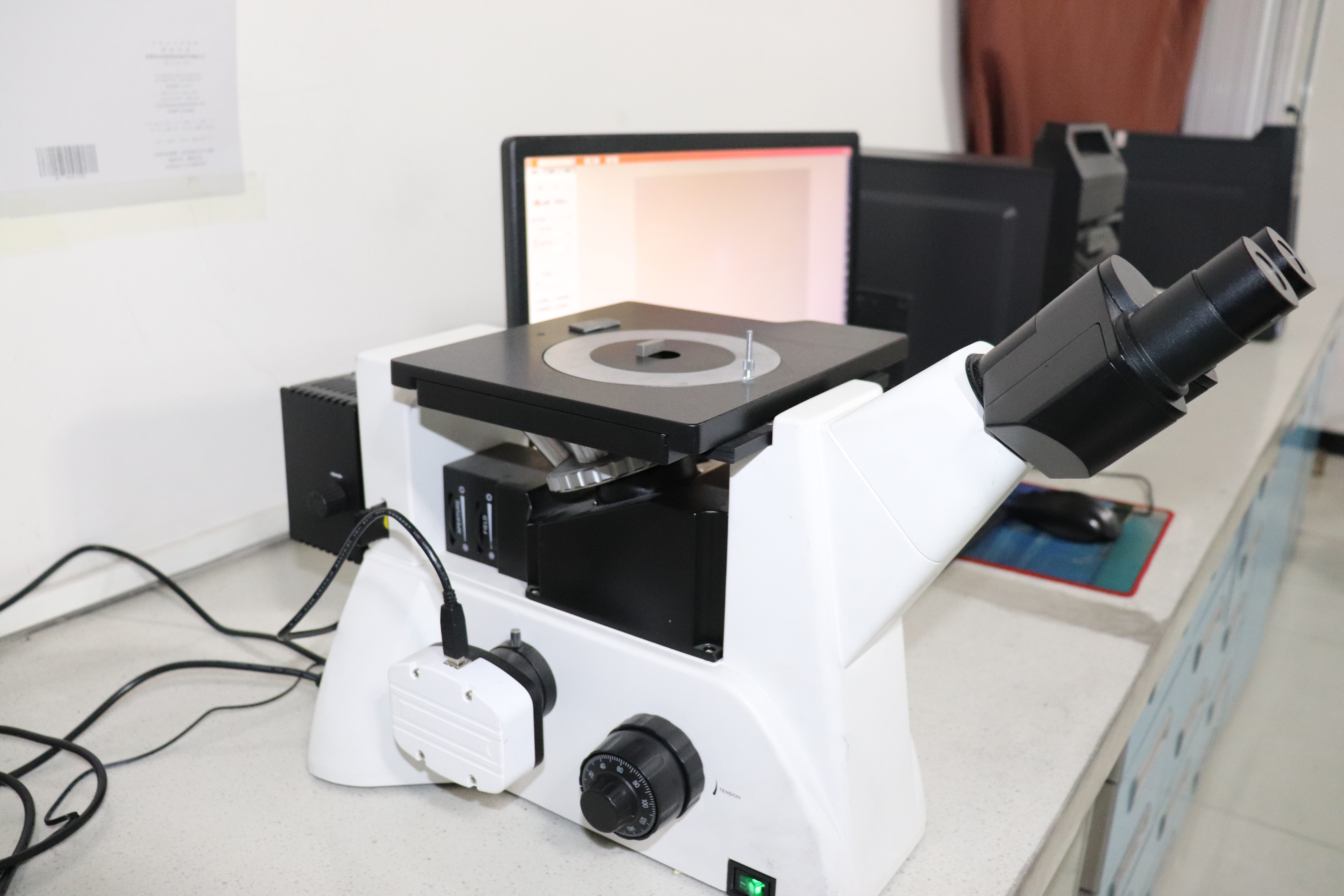

Cemented carbide testing equipment

Metallographic microscope is a commonly used metal material testing equipment, which can be used to study the microstructure, composition and performance of cemented carbide. Here are some examples of metallurgical microscopy in cemented carbide applications: 1. Microstructure analysis: Metallog...Read more -

Determination of cobalt magnetism of cemented alloys

Tungsten carbide cobalt magnetism, also known as the saturation magnetization strength of the alloy, is actually the saturation magnetization strength of the magnetic material cobalt. The cobalt magnetism of tungsten carbide is also based on the ratio of its magnetic material cobalt content to th...Read more -

Tungsten carbide coercivity magnetism

Tungsten carbide coercive magnetism is the magnitude of the reverse magnetic strength required to completely demagnetize a magnetic material. The coercivity magnetism of carbide decreases with increasing cobalt content and increases with finer grain size. The coercivity magnetism is measured to e...Read more -

Effect of vacuum sintering process on tungsten carbide moulds

The role of vacuum sintering of tungsten carbide mold mainly has the following aspects: 1. Improve hardness and toughness: Vacuum sintering is a method of sintering tungsten carbide powder into cemented carbide by using high temperature and high pressure. Through vacuum sintering, tungsten carbi...Read more -

What is Cold Heading

Cold heading is a metalworking process whereby a metal bar or wire is transformed from a larger diameter round bar or wire to a smaller diameter steel wire or rebar by applying a strong force to it in a die at room temperature, while also changing the shape of the metal cross-section. The process...Read more -

How long is the service life of cold heading die

The service life of cold heading dies depends on many factors, including materials used, processed materials, equipment temperature, surface treatment and so on. Generally speaking, the life of cold heading dies can reach millions or tens of millions of impacts. In order to ensure the life of co...Read more -

Ways to extend the life of tungsten carbide cold heading dies

To prolong the life of cold heading dies, we can mainly start from the following aspects: 1. Reasonable selection of mold materials: The material of cold heading molds should be selected according to the type of steel produced, hardness, cross-sectional shape and working environment and other fac...Read more -

Market demand for tungsten carbide cold heading dies

Tungsten carbide cold heading die is a common hard alloy cold heading die. Its main raw materials are tungsten carbide powder and cobalt powder, which are made through multiple processes such as high temperature smelting. Common tungsten carbide cold heading dies include tungsten-cobalt series, t...Read more -

Application of tungsten carbide moulds in fasteners

Tungsten carbide molds are widely used in fastener manufacturing, mainly in the following aspects: 1. Manufacture of screws: Tungsten carbide material has extremely high hardness and wear resistance, and can be used to manufacture various types of screw molds, including parts such as heads, threa...Read more